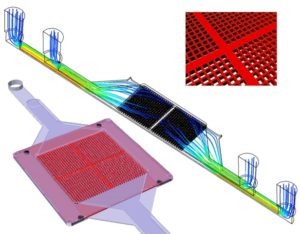

The aim of a simulation-based analysis of separators is to optimise the separation process, increase the efficiency of the material separation and thus the yield.

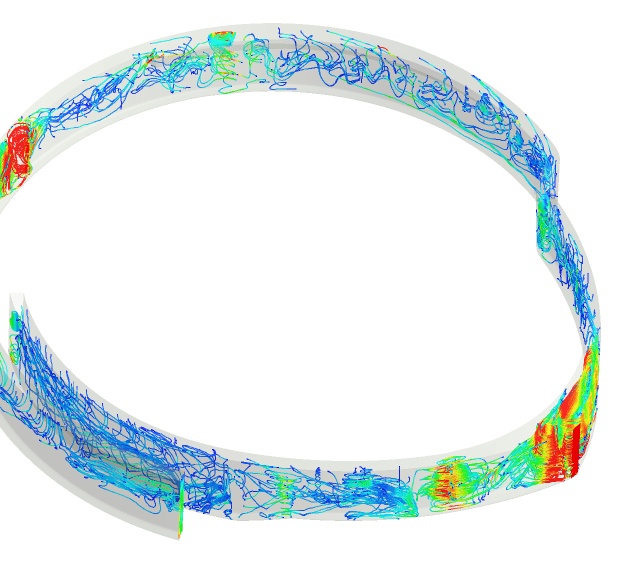

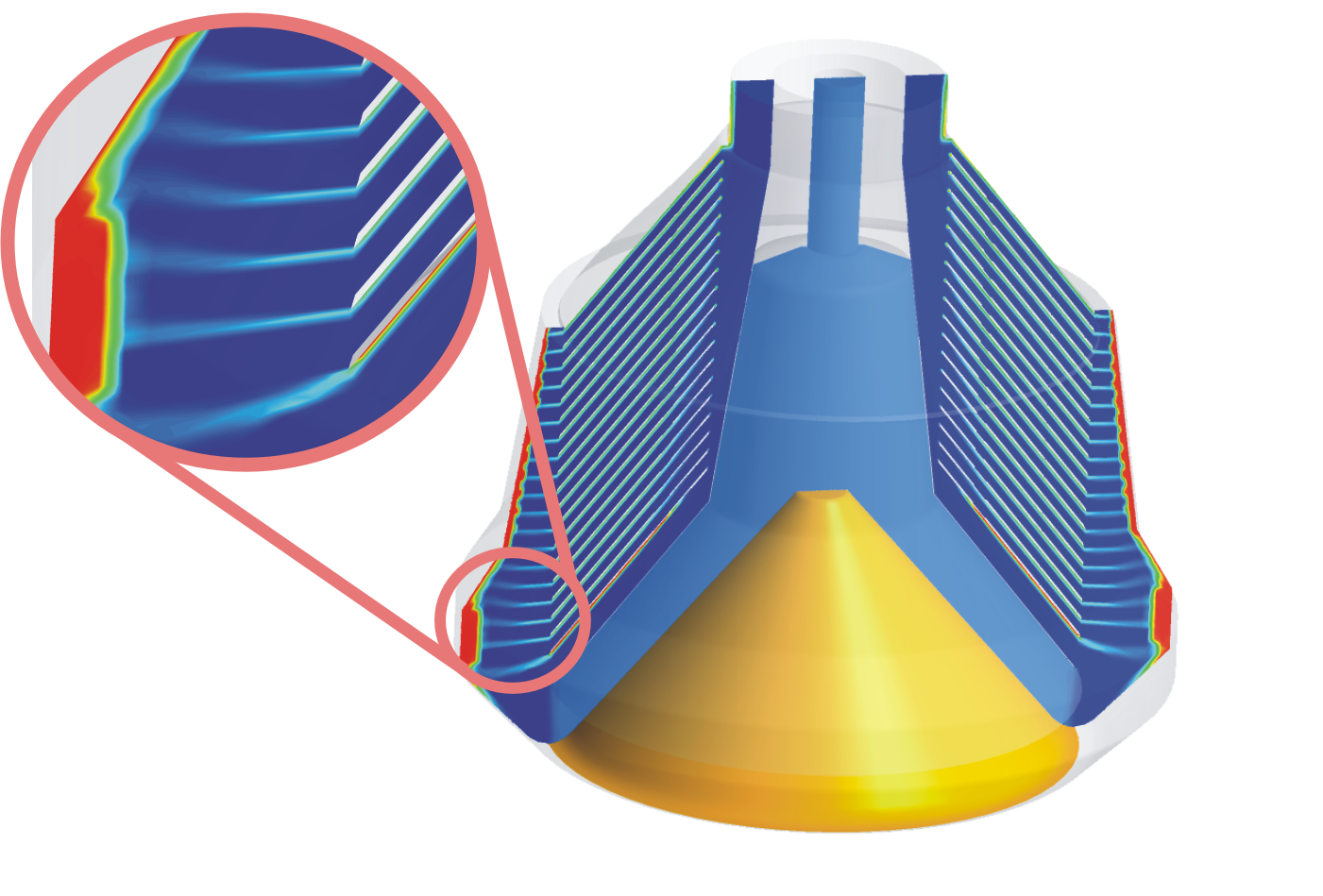

The multiphase models used take into account both the influence of solid particle collisions and high particle concentrations on the flow conditions.

Specifically, the 3D flow conditions, the concentration distributions of the substances involved, the resulting separation rate as a function of particle diameters or the influence of different operating parameters on the separation behaviour can be supplied. In addition, erosion phenomena and deposits can be investigated and the mechanical stress on the components quantified.